Mineral development company Cornish Lithium announced on 24 October that it has started production of refined lithium hydroxide monohydrate (LHM) using lithium extracted from granite in Cornwall, in what’s being claimed as a first for the UK.

The group has produced the demonstration-scale samples at its Trelavour plant, a brownfield industrial site in Cornwall, using material mined from a repurposed former china clay quarry, and a proprietary low-carbon processing technology.

LHM is a key raw material for lithium-ion batteries, which continue to be foundational in modern-day electronics, and systems such as electric vehicles (EVs), smartphones and energy storage.

Geopolitical developments have heightened the urgency of lithium-sourcing in many parts of the world in recent years, and intensified the race to develop a homegrown lithium industry in the UK, a contest in which several firms appear to be vying for a leadership position.

Cornwall is said to be home to one of the largest lithium deposits in Europe. Cornish Lithium’s publicity says the area has enough lithium to power at least 50% of all EVs expected to be produced in the UK by 2030.

Commenting on the announcement, Cornish Lithium CEO Jamie Airnes said:

“This is a watershed moment for the UK’s industrial capabilities and economic resilience. For the first time ever as a country, we have now demonstrated the ability to produce one of the raw materials on which we all increasingly rely. It is testament to the strength of our research, our innovative approach, and the dedication of the Cornish Lithium team.

“This once-in-a-generation breakthrough marks the latest stage in Cornish Lithium’s journey to secure a domestic supply of lithium for the UK automotive and battery industries, securing the UK’s future jobs, lithium supply chain and economic growth.”

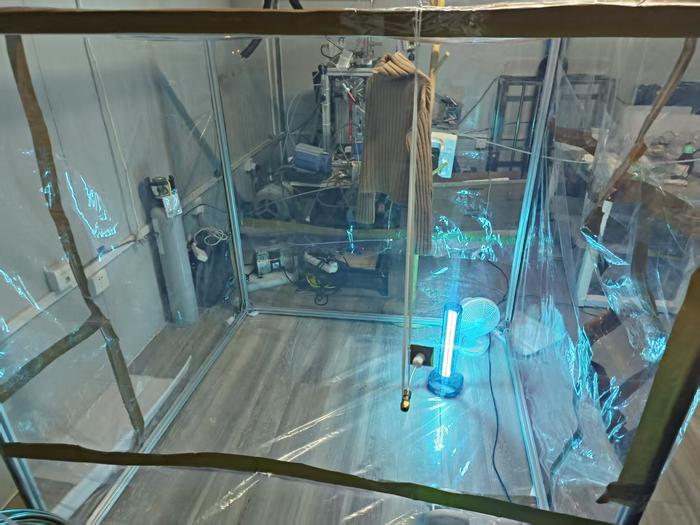

The refined lithium hydroxide samples were produced at Cornish Lithium’s demonstration plant, which incorporates all processing stages including crushing and grinding the rock, separating the lithium-bearing minerals, and processing them to produce a refined LHM.

Launched a year ago, the plant uses patented, low-carbon processing technology which the group said was developed over many years of intensive research and development. In early 2025, Cornish Lithium acquired full IP and associated patents from Australian company Lepidico. “The Lepidico process has shown to be highly effective and has now been fully optimised by improvements made at the demonstration plant,” said Cornish Lithium, which plans to market the technology internationally.

The construction of the hydrometallurgical section of the plant was supported by funding Innovate UK through the Automotive Transformation Fund’s (ATF) Scale up Readiness Validation competition (SuRV).

Cornish Lithium said it plans to build a full-scale lithium processing and refining plant with an annual capacity of up to 10,000 tonnes of LHM, which is expected to commence full-scale production in 2029.

Following the announcement of £35m of funding from institutional investors, the National Wealth Fund (NWF) and TechMet, the group said it has also launched a new crowdfunding campaign to allow its wider community of shareholders and supporters the chance to invest in the next stage of growth. The campaign is hosted on the Crowdcube investment platform, here.