At a San Antonio research campus, a four-story-tall contraption breaks apart the molecules of Texas shale gas, producing hydrogen and carbon.

But that carbon doesn’t form CO2 gas and drift into the atmosphere where it fuels global warming. Instead, it comes out as black powder that can be stored in bins, moved by railcar and even made into commercial materials.

“It’s a lot easier to handle solid carbon than it is to handle CO2,” said Zach Jones, CEO of Graphitic Energy, which commissioned its pilot project in San Antonio this year.

Graphitic is part of a small landscape of startups developing new ways to utilize some of the billions of tons of carbon in fossil fuels that end up billowing from smokestacks as waste every year. To separate the carbon from methane gas, Graphitic uses a well known process called pyrolysis, which has typically been considered far too energy intensive for economic viability. However, the company says it formulated an undisclosed chemical catalyst that reduces the required power input by close to 90 percent.

Now it hopes to turn a profit selling hydrogen, a clean burning fuel, and using the carbon soot to produce graphite, a critical mineral currently sourced primarily from China.

“We are able to monetize the carbon,” Jones said. He isn’t the only one chasing this target.

Another company in San Antonio, Carbon Free, built hardware to crystalize CO2 emissions into calcium carbonate, or baking soda, and is working in partnership with U.S. Steel. In Houston, Cemvita, has engineered microbes that recycle CO2 into chemicals or even cooking oil, and Dexmat, has devised pure carbon nano-materials which they call a replacement for metals.

In the near term, all these endeavors combined won’t divert more than a negligible fraction of humanity’s greenhouse gas emissions, even as global temperatures and fossil fuel consumption continue to rise. But in the long term, some scientists hope these technologies could help change the view of carbon as a waste product to be discharged into the atmosphere.

“It’s the economics that need to command this,” said Frederic Clerc, director of the Carbon to Value Initiative, an accelerator for carbon technology startups at New York University. “These days, in the U.S., it’s all about economics. It’s not really about the environmental benefit.”

The program has graduated 35 companies since it was launched in 2020 (Graphitic Energy is not among them). Their technologies may succeed, Clerc said, when big corporations can make more money selling their carbon byproduct than they would save by discarding it. But that can only happen after these technologies achieve large-scale production and the economic efficiencies it entails.

“It’s all about scale,” Clerc said. “To be competitive in commodity markets you need to be at a very big scale.”

That raises another challenge: many of these technologies require huge amounts of energy for large-scale production, but they’re emerging just as an explosion of artificial intelligence projects has created yearslong queues to buy power or power generating hardware.

Companies say they’ll use renewable sources to avoid creating more carbon emissions. However, such steep growth in power demand could actually hinder broader efforts to decarbonize.

“You could have taken that energy and used it to supplement the grid,” said James Tour, a professor of chemistry and material science and nanoengineering at Rice University. “Just because it comes from wind and solar doesn’t mean you can abuse it, doesn’t mean you can use it for stupid things.”

Not all these ideas are stupid, he said. It depends on the processes used, the energy input required and the commodity produced in the end.

“There’s a ton of money poured into this type of thing,” Tour said.

Most carbon technology startups hope to partner with large scale industrial emitters and assume custody of the carbon at their smokestacks. German company enaDyne uses a process called plasma catalysis to recycle CO2 and hydrogen back into hydrocarbon fuels “at or below the price of fossil-based alternatives.” Houston-based Mars Materials uses a process called nitrilation to convert CO2 into a common industrial chemical.

New York-based Air Company produces alcohol using an extremely energy intensive process called electrolysis to turn water and captured CO2 into ethanol. So far, the company has produced vodka and hand sanitizer.

Carbon Capture

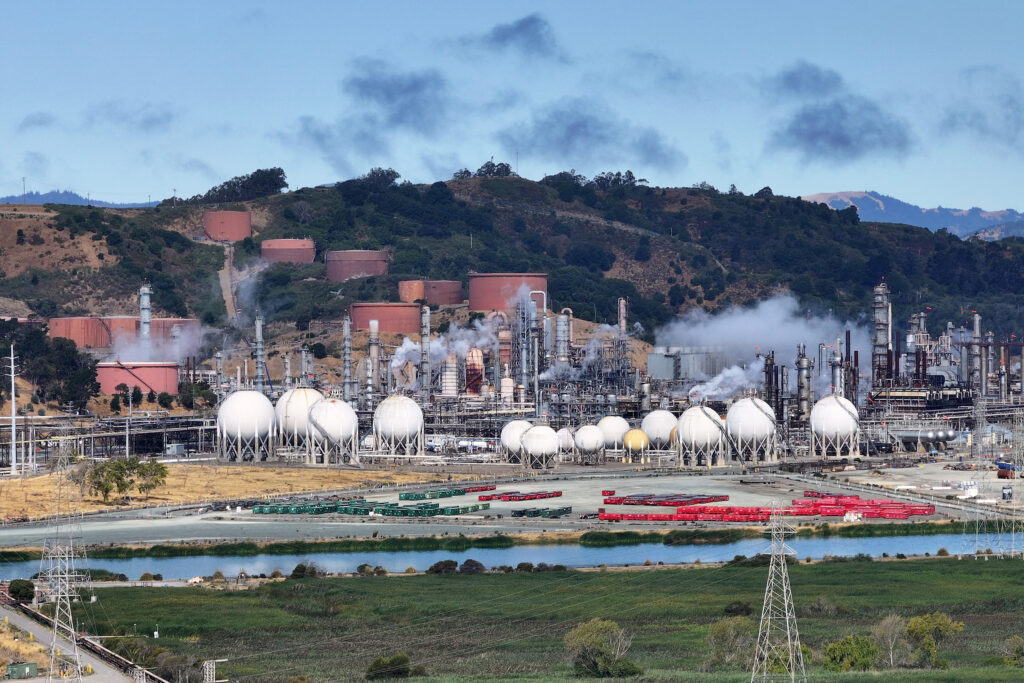

If some of these companies succeed, they could be the key to widespread deployment of carbon capture systems at industrial emission sources. Such systems have existed for decades but aren’t widely used. Meanwhile, other kinds of emission control systems have drastically reduced the release of many different toxic substances from tailpipes and smokestacks over the last 50 years.

With carbon, the difference is the enormous volumes involved. Carbon constitutes most of the mass in fossil fuels. When burned, it binds with oxygen into CO2 gas. A large power plant can create hundreds of tons per day. In 2024, global energy-related emissions of CO2 were estimated at 38 billion tons. So, the proliferation of carbon capture systems is hung up on questions over what to do with such an unwieldy amount of gas, and who will pay to do it.

“Unless you have a downstream pull, a demand, it’s going to be tough to make the case just to capture CO2,” Sravanth Gadikota, co-founder of a New York-based company called Carbon to Stone. “The technology has been around but nobody is implementing it as much as we thought they would have.”

Gadikota’s company has systems to mineralize CO2 emissions at their source into a solid substance that can be used in cement and other building materials. It started in 2018 as a research group at Cornell University, funded by the U.S. Department of Energy. This year it plans to launch its first commercial pilot projects at a steel mill and cement kiln. Each is designed to process up to 8 tons of CO2 per year—barely a whiff in earth’s atmosphere, but a hopeful step towards potentially larger deployments.

For now, there’s only one developed commercial use for massive amounts of CO2. Oil companies inject it underground to squeeze up more oil. They’ve done it for decades with naturally occurring CO2. A few are using captured emissions, but at a much higher cost that requires financial support from the government. It also requires building pipelines from emission sources to oilfields. Virtually all existing carbon capture facilities in the U.S. today provide CO2 for oil production. The next largest users of CO2 are food and beverage companies.

This story is funded by readers like you.

Our nonprofit newsroom provides award-winning climate coverage free of charge and advertising. We rely on donations from readers like you to keep going. Please donate now to support our work.

Donate Now

The Biden administration pushed to develop the practice of underground injection for disposal of CO2 without any oil involved, but its uptake has so far been minimal. It also requires a new web of pipelines and depends on government funding. Outside of subsidies, companies don’t make any money by capturing and injecting their CO2.

“At the end of the day, somebody has to be willing to pay the cost,” Gadikota said. “It has to make business sense.”

For years, climate and environment groups have denounced government spending on carbon capture as a “false solution” that prolongs the use of fossil fuels and consumes resources without making significant emissions reductions. Capturing carbon at smokestacks doesn’t address the ubiquitous emissions of raw methane, a greenhouse gas more potent than CO2 in the near term, in the oilfields and all along the gas supply chain.

To address climate change, many groups argue, nations should focus fully on building and improving renewable power projects to replace and eventually discontinue the use of carbon-based fuels entirely.

“Subsidies and regulatory mechanisms meant to accelerate carbon capture for (power) generation aren’t really a reasonable substitution for fundamentally clean energy,” said Jeremy Fisher, senior advisor on climate and energy at the Sierra Club.

However, there’s still no indication that an end of life is approaching for fossil fuels, which still account for the vast majority of energy consumed globally. Despite a decade of booming expansion of wind and solar power projects, global consumption of coal, oil and gas continues to rise, along with carbon emissions. Now the swift emergence of artificial intelligence and its astronomical energy demands is helping drive a fresh buildout of gas-fired turbines and pushing any potential phase-out of fossil fuels far beyond the horizon.

“We’re not going to solve the climate problem simply by putting up windmills,” said Charles McConnell, a former assistant energy secretary with the Obama administration. “We’ve got to have a way to address the emissions that are associated with fossil fuels.”

Decarbonizing energy will require a combination of every potential solution on the table, said McConnell, now executive director of the Center for Carbon Management in Energy at the University of Houston, from renewable power and electric cars to alternative fuels and technologies for emission control.

Unlike most potential solutions, he said, carbon capture has stayed outside the fray of America’s culture wars as both sides kept their distance. Environmentalists disliked that it gave money and a lifeline to fossil fuels, while archconservatives disliked that it acknowledged the hazards of carbon emissions.

In between, political support for carbon capture has come primarily from large oil and gas companies, who see it as good for business.

“These companies are interested in increasing the volume of fossil fuels that are produced,” said John Hall, president of the Houston Advanced Research Center. “There is a recognition that in order for natural gas to remain a viable alternative, they’ve got to figure out a way to reduce emissions.”

That’s a big reason why Congress preserved Obama-era tax credits for carbon capture projects when it passed Trump’s budget bill last month, even as it slashed most other climate-focused incentive programs.

While decarbonization may have faded from vogue in Washington, D.C., the European Union continues to tighten and expand its climate regulations, at least for now.

“Most of the big companies in Texas are international players, particularly in Europe,” Hall said. “They have to meet climate goals there.”

Where the Magic Happens

Atop three stories of scaffolding, chief technology officer Patrick Hanks pats a large red tub. Forty feet tall and one foot wide, this “carbon formation vessel” is where the magic happens. It takes two days to heat up to 700 degrees Celsius and two days to cool down, but it’s designed to run 24/7. Inside the vessel, under extreme temperature, molecules of methane break apart into hydrogen and carbon.

Graphitic Energy plans to partner with big industrial companies that use hydrogen as fuel, for fertilizer or in chemical production. Currently, hydrogen is produced from methane through a process that requires less energy but also releases the carbon into the atmosphere as CO2.

Graphitic would provide its partners with hydrogen at a price buttressed by the income they hope to make selling carbon graphite, a critical mineral.

“You make so much carbon for the hydrogen you are producing,” said Hanks, a former ExxonMobil employee with a PhD in chemical engineering. “No supply chain dependencies on China or digging it out of the ground. We make limitless amounts from domestic natural gas.”

The company’s process would produce roughly three times as much graphite as hydrogen. It’s not the kind of premium graphite used in batteries and fuel cells, but a lower-grade mineral widely used in metallurgy and machinery.

“I do think there is a market for that,” said Marek Locmelis, an associate professor with the Bureau of Economic Geology at the University of Texas at Austin.

He said China currently dominates almost all of the world’s graphite supply. Meanwhile, the U.S. energy and defense departments are trying to establish domestic manufacturing capabilities. The country’s first graphite mine began production last year in Louisiana.

“It can take 10-plus years to get a natural graphite mine online,” Locmelis said. “If you can use this methane source instead of opening a new mine, then it will save you a lot of money.”

About This Story

Perhaps you noticed: This story, like all the news we publish, is free to read. That’s because Inside Climate News is a 501c3 nonprofit organization. We do not charge a subscription fee, lock our news behind a paywall, or clutter our website with ads. We make our news on climate and the environment freely available to you and anyone who wants it.

That’s not all. We also share our news for free with scores of other media organizations around the country. Many of them can’t afford to do environmental journalism of their own. We’ve built bureaus from coast to coast to report local stories, collaborate with local newsrooms and co-publish articles so that this vital work is shared as widely as possible.

Two of us launched ICN in 2007. Six years later we earned a Pulitzer Prize for National Reporting, and now we run the oldest and largest dedicated climate newsroom in the nation. We tell the story in all its complexity. We hold polluters accountable. We expose environmental injustice. We debunk misinformation. We scrutinize solutions and inspire action.

Donations from readers like you fund every aspect of what we do. If you don’t already, will you support our ongoing work, our reporting on the biggest crisis facing our planet, and help us reach even more readers in more places?

Please take a moment to make a tax-deductible donation. Every one of them makes a difference.

Thank you,