Leaders of a pioneering project to develop 3D printed infrastructure and components for the water sector will be sharing insights from five years of research.

The Water Industry Printfrastructure project has been led by United Utilities in partnership with ChangeMaker3D, Manchester Metropolitan University’s PrintCity and Scottish Water. Funding came from Ofwat’s Water Breakthrough Challenge with Spring Innovation as the knowledge-sharing partner.

The project team will join a showcase webinar facilitated by Spring on 28 November 2024, to highlight learnings and discuss how the research, which concludes in early 2025, could be scaled-up to provide resilient and sustainable infrastructure for water.

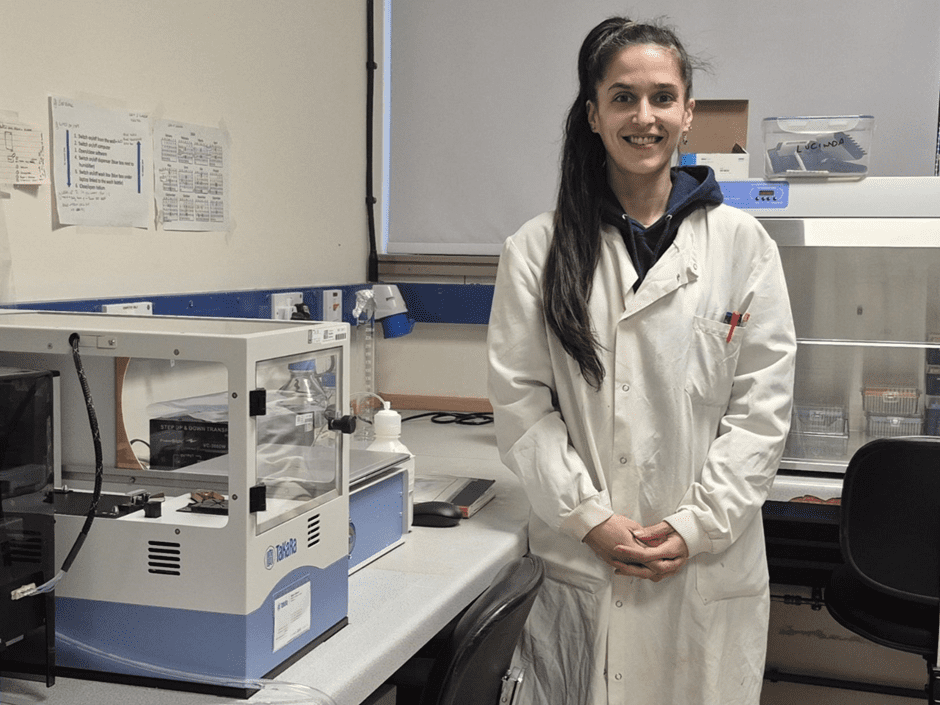

Both concrete and polymer 3D printing were explored in a series of studies since the Printfrastructure project launched in 2023, achieving several UK water industry firsts. They include a project headed by PrintCity, a 3D manufacturing facility based within Manchester Metropolitan University, to create replacement parts through 3D scanning, computer aided design (CAD) and 3D polymer printing.

Three printed items – a wastewater jet nozzle, CCTV skid plate and trough for water monitoring instruments – are being used by United Utilities in everyday operations, following rigorous testing and trials. Laboratory equipment has also been printed and is being used by both Scottish Water and United Utilities.

For water companies, the ability to print replacement parts on demand can address challenges around equipment availability, delivery times and rising costs, helping reduce reliance on suppliers and build in-house resilience. Faster project turnaround time, reduced cost and lower environmental impact are also key benefits.

Another industry first saw the opening of a temporary 3D concrete printing hub at United Utilities’ Wigan Wastewater Treatment Works in June 2024. The facility was created with technology from 3D print specialists ChangeMaker3D, which began working with United Utilities in 2021 when it was selected to take part in the company’s Innovation Lab programme.

The hub printed a range of concrete infrastructure, including combined sewer overflow chambers and Industrial Emissions Directive containment walls. Printed assets will be used on United Utilities and Scottish Water sites in future. The facility was also used as a demonstration facility to showcase the technology to the water and construction sectors, along with other industries.

Findings from the polymer and concrete Printfrastructure studies, as well as the group’s research into carbon and social value and commercialisation of 3D printing, will be shared at the upcoming webinar.

Lisa Mansell, chief engineer, innovation and carbon, United Utilities, said: “The Water Industry Printfrastructure project is transforming 3D construction printing from an innovation into an accessible tool to support everyday operations, drive efficiencies and help meet environmental goals.

“We are seeing tangible results from the printing processes developed by the project team, which have potential for adoption at scale. The technology presents many more exciting opportunities for the sector, and we look forward to showing just what is possible.”

Nick Hurst, technical specialist at Manchester Metropolitan University – PrintCity, said: “This collaborative project is helping turn 3D printing into business-as-usual, an approach that will be game-changing for the sector.

“Some of the project’s outcomes – such as the successful printing of polymer spare parts – are already making a difference on the ground and delivering significant carbon, cost and labour savings. PrintCity has been working with the operational teams to enhance the designs, improving durability and ensuring parts can be maintained more effectively.

“Custom parts have also been designed and 3D printed. As the project nears completion the showcase webinar is a great opportunity for the team to share insights with the rest of the sector.”

Ian Watt, capital investment net zero manager, Scottish Water: “The water industry is planning to spend a record amount on infrastructure during the next asset management period, with an ambitious capital programme that can only be delivered through new approaches and innovation.

“The Printfrastructure project has shown that 3D construction printing can deliver a 25% reduction in carbon, 20% cost saving and 55% reduction in labour, versus traditional methods. Assets can be built quickly, with a reduction in materials, creating a safer, more efficient working environment and helping meet carbon goals.

“After three years of collaborative research, feasibility studies and rigorous testing, we are on the cusp of being able to scale-up this exciting technology and look forward to showing the sector what can be achieved with 3D printing.”