A long-standing grail of chemicals manufacturing is a less emissions- and energy-intensive process for manufacturing ammonia. One of the Earthshot Prize nominees, Nium unveiled an advanced catalyst manufacturing platform at Milton Park, Oxfordshire in October. Supported by Innovate UK, the work relies on nanotechnology to take hydrogen from water and nitrogen from the air, dispensing with the need to burn fossil fuels. The milestone potentially positions it as a front-runner amongst contenders to replace an industrial process that has been the standard for a century.

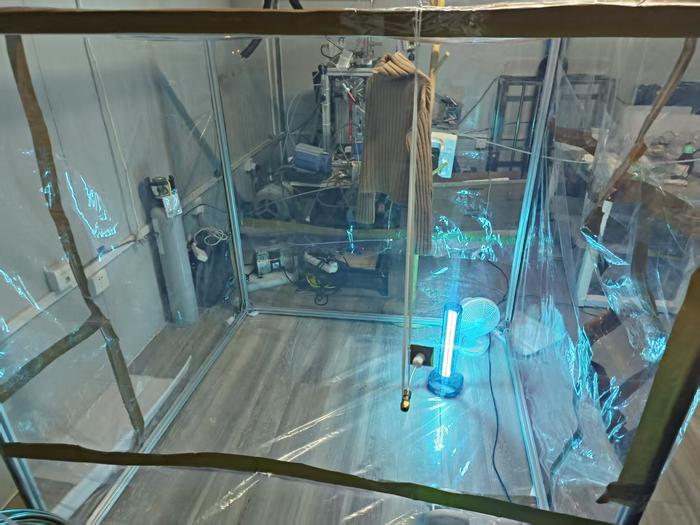

Nium has designed, patented and built a unique catalyst manufacturing platform, which is housed in its bespoke R&D facility (the ‘Nanosphere’). This is dedicated to manufacturing the catalyst at the heart of this new approach to making ammonia. Inside the system, a specialised process is used to coat fine powders with atomic-level precision, transforming them into Nium’s unique, high-performance materials.

Ammonia is a chemical widely used in agriculture as fertiliser, in industrial processes and as a potential clean fuel source. However, the process requires large amounts of energy to extract hydrogen from natural gas and to drive the high-pressure, high-temperature Haber-Bosch process.

What it does

Traditional ammonia production produced using this method releases around two tonnes of CO₂ for every tonne of ammonia produced. In contrast, Nium’s catalyst production breakthrough uses nanotechnology to take hydrogen from water and nitrogen from the air, producing ammonia with far lower energy requirements and minimal emissions.

Put simply, it creates ammonia without the need to burn fossil fuels, producing much less pollution and waste. The process is greener because it can be powered by renewable energy sources, avoids fossil fuels and generates very little waste. Beyond ammonia, the technology has the potential to create advanced materials like high-performance graphite and ceramics, all using this solvent-free, low-waste approach.

The ‘catalyst creator’ has seemingly attracted national attention for its potential to build domestic capability in advanced manufacturing. It was recently showcased during a visit from Professor Paul Monks CB, the UK Government’s Chief Scientific Adviser at the Department for Energy Security and Net Zero (DESNZ).

Professor Monks toured the facility, witnessing Nium’s pioneering Nanosphere system first-hand and commented that he was “fascinated to see innovation happening at scale at Milton Park.” The visit highlighted the importance of technologies like Nium’s in driving the UK’s clean growth agenda and strengthening advanced manufacturing.

Nium is preparing for the first full operational runs of the new platform this autumn, which will mark the transition from a prototype to a production-ready facility. These upcoming tests will establish the system’s performance, confirming its capacity to reliably produce Nium’sadvanced catalyst materials at scale.

These catalysts are the key enabling component for Nium’s clean ammonia technology. They will be deployed within the company’s modular ammonia production systems, which are designed to be used on any site, at any scale. This opens up a vast range of applications, from producing decarbonised chemicals and clean shipping fuel to creating low-carbon fertilisers for agriculture.

According to Phil Hunter, Nium’s Co-Founder and CEO, having the room to grow at Milton Park has been critical to developing the platform.

He said: “The challenge with creating revolutionary new materials isn’t just in their design, but in their manufacturing. We found that no off-the-shelf equipment could deliver the precision needed for our advanced catalysts, so we had to invent our own solution from the ground up. As we outgrew our previous labs, Milton Park gave us the space and flexibility to build this unique manufacturing platform within our own bespoke, purpose-built R&D facilities.

“Having the freedom to create our own labs under Milton Park’s Local Development Order has been truly transformational and made commissioning this world-first platform possible.”

Tom Booker, Commercial Manager at MEPC Milton Park, said: “Nium’s launch is a fantastic home-grown story of British innovation. It was excellent to support the team’s move into the Park last year and since then, see them grow their operations before delivering a UK-first of this scale.

A crowded field?

Nium’s technology sits within a competitive landscape of emerging ammonia production methods. Other approaches include artificial photosynthesis and electrochemical nitrogen fixation.

For instance, research into artificial photosynthesis aims to mimic natural processes to convert sunlight, water, and CO₂ into ammonia. Several challenges appear to remain with scaling the approach for industrial use. For example, developing catalysts that can convert nitrogen into ammonia under ambient conditions remains a goal. Efficient light absorption

and charge separation are crucial for driving the nitrogen reduction reaction, and some groups are exploring semiconductor materials that are optimized to absorb a broad spectrum of light and facilitate effective charge transfer, work that requires advanced materials engineering.

Similarly, another avenue being explored is electrochemical methods which can directly convert nitrogen and water into ammonia using electricity, which could be powered by renewable sources.

Nium’s focus on nanotechnology and its ability to operate at lower temperatures and pressures appear to distinguish its approach. This latest announcement of the attainment of scalability and manufacturing milestones appears significant.