VERONA, Wis.—You only need a glance at the “Intergalactic Headquarters” of Epic Systems to realize the corporate campus of this medical records software company is not a typical office park.

Buildings resemble Willy Wonka’s chocolate factory, the Emerald City of Oz and Hogwarts Castle. There’s a treehouse conference room, a “Deep Space” auditorium and a stairway in “Heaven.”

However, what’s buried beneath the fantasy-themed campus of one of the nation’s largest privately held tech companies is arguably more unusual and, from a climate perspective, potentially far more significant.

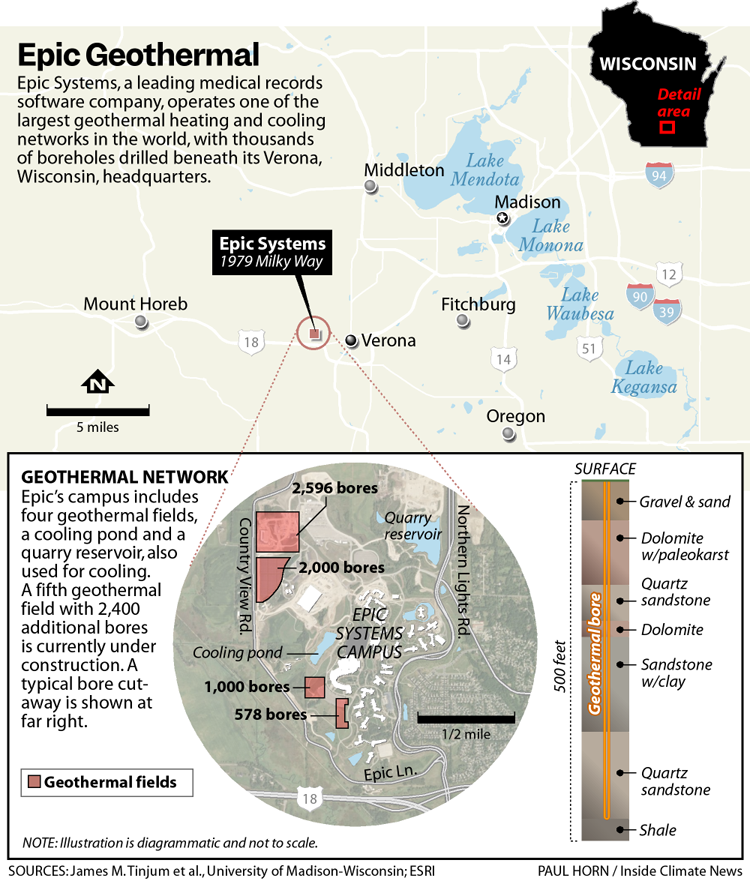

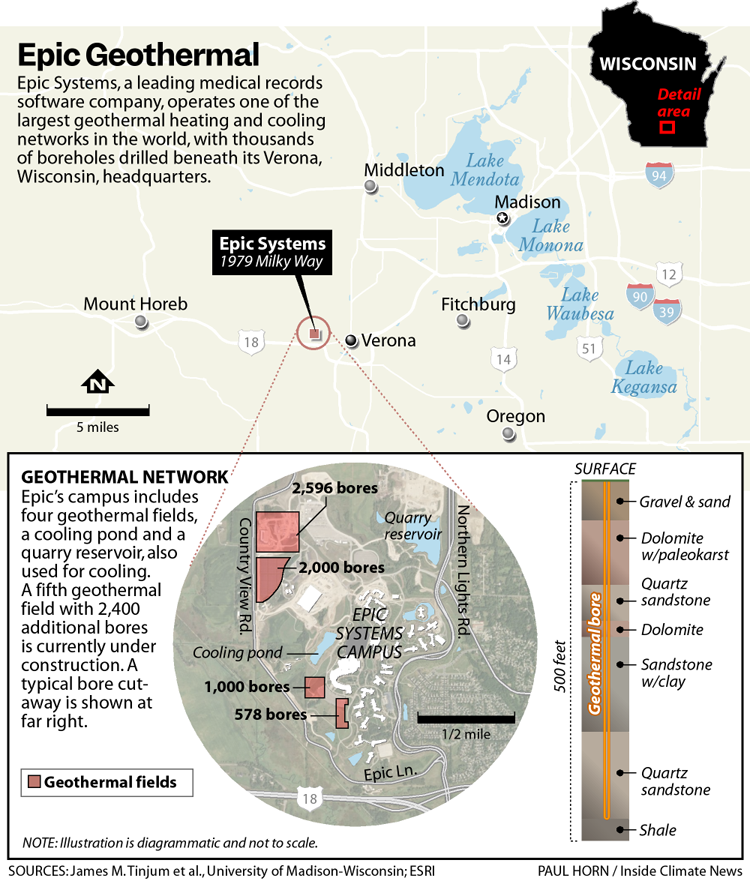

Roughly 6,100 boreholes, each drilled hundreds of feet into the earth, comprise one of the largest geothermal heating and cooling networks in the world. Electricity from a nearby wind farm and a field of solar panels pumps approximately 6 million gallons of water through a closed network of pipes that distribute hot and cold water across the sprawling 410-acre campus.

If stretched end to end, the pipes in the boreholes alone would extend from here to the Florida panhandle.

Epic, whose high-efficiency heating and cooling system was highlighted this summer by the U.S. Department of Energy, is now expanding its network by adding 2,400 more boreholes with drilling that began last month.

“Once you start putting numbers to things, the scope and scale gets a little bit crazy,” Scott Brabender said during a recent tour of the campus. He’s a vice president and senior mechanical engineer with Salas O’Brien, the firm that designed much of Epic’s geothermal system and is overseeing its current buildout.

Epic’s buildings use approximately one-quarter the amount of energy as typical office buildings, according to Derek Schnabel, the director of facilities and a senior mechanical engineer at Epic. Some of those savings come from high-efficiency lighting, additional insulation and weatherization, but more than half the energy reduction comes from the geothermal system, Schnabel said.

Epic, which houses the medical records for 325 million patients, has been drilling additional boreholes at its headquarters on the outskirts of Madison, the state capital, since it completed its first borefield in 2006. The relatively shallow vertical bores, ranging from 300 to 800 feet deep, tap thermal energy from the near-surface where temperatures are approximately 50 degrees Fahrenheit year-round.

Geothermal heating and electricity production have been around for more than a century in regions with high-temperature resources near the Earth’s surface. However, geothermal heating and cooling, which can be harnessed in most locations worldwide, is a more recent development.

At the same time, enhanced geothermal systems that utilize hydraulic fracturing techniques developed by the oil and gas industry, and other advanced methods to drill deep underground to generate steam for electricity production, are also seeing increased interest.

In the case of geothermal heating and cooling, the Earth acts as a thermal equalizer, warming or cooling water piped through boreholes until it reaches a temperature similar to that of the surrounding rock and sediment. Once aboveground, the ambient-temperature water is then further cooled or heated.

At Epic, this happens in one of several central plants where high-efficiency electric heat pumps provide the hot and cold water that heats and cools the entire campus.

Epic’s thousands of boreholes also serve as a thermal battery, drawing excess heat from buildings in the summer and storing it underground. This stored heat is then released back into the buildings in the winter, providing added efficiency to the system.

“They harvest energy from that battery in the heating season and then in the cooling season, they’re recharging the battery by putting heat back into the subsurface,” said James Tinjum, an associate professor of civil and environmental engineering at the University of Wisconsin–Madison, and director of the school’s geological engineering program.

Tinjum and others at the university partnered with Epic in 2014 to install a fiber-optic monitoring network inside the largest of the company’s four borefields, allowing the researchers to track its performance over time.

Nearly 40 percent of all energy consumed in the U.S. is used by buildings, with more than half of that going to heating and cooling, according to the Department of Energy.

“We’re talking about a tremendous source of energy consumption, and companies like Epic have realized that there’s a better way to do it,” said Ryan Dougherty, president of GeoExchange, a geothermal heat pump industry group.

Utility Interest and Questions

With approximately 12,000 on-site employees spread across dozens of buildings, Epic’s campus approaches the size and scale of a small town. As utility companies across the country begin to pilot smaller, neighborhood-scale geothermal heating and cooling projects, Dougherty said Epic’s heating and cooling system provides an example of a larger, “marquee” project.

It “can serve as an instructive example of how to do something that many others might think is too big and too complex,” he said.

Utilities are looking to transition away from gas either to meet climate goals or to comply with state regulations. Burning natural gas releases carbon dioxide into the atmosphere. Methane, the primary component of natural gas, is also released through leaks or intentional venting across the gas supply chain from production wells and compressor stations to home stovetops and ovens.

Methane is a potent greenhouse gas that is far more effective than CO2 at warming the planet in the 20 years after it is released. Emissions from the gas sector exceeded 6 million tons in 2022, according to the U.S. Environmental Protection Agency’s most recent annual greenhouse gas inventory.

That’s the equivalent of one year of greenhouse gas emissions from 132 coal-fired power plants when assessing methane’s 20-year climate impact, according to EPA figures.

Eric Bosworth, a geothermal expert who runs the consultancy Thermal Energy Insights, praised Epic’s system but said he wished more information about the project were publicly available.

“They’re obviously running a massive campus there in Wisconsin on a shared network, which is great,” Bosworth said. “But the next question from the utility [perspective] is going to be, ‘OK, what do the loads look like, what’s the performance and what did it cost to put in?’”

Bosworth oversaw construction of the nation’s first utility-led geothermal network while working for gas utility company Eversource. That system, which was completed in 2024, was a relatively small-scale pilot project in Framingham, Massachusetts, with 90 boreholes that provide heating and cooling for 31 residential and five commercial buildings.

As utility companies look to scale up, a key question is cost, Bosworth said.

Epic shares data on the performance of its system but declined to comment on its costs.

“We just thought it was the right thing to do,” Schnabel, Epic’s director of facilities, said of the installation. “As a private company, we can make investments that take a little bit longer to pay back if we really believe in them. It was just that simple.”

The company’s geothermal system has a 15- to 20-year return on investment and the initial borefield is already paid off, a spokesperson for the company said in a written statement.

Geothermal has higher upfront costs than other heating and cooling methods, largely due to the added expense of drilling. However, the technology’s high-efficiency, low-power demands and durability pays for itself over time.

This story is funded by readers like you.

Our nonprofit newsroom provides award-winning climate coverage free of charge and advertising. We rely on donations from readers like you to keep going. Please donate now to support our work.

Donate Now

The pipes that are used to cycle water through the boreholes and to individual buildings are expected to last 80 years or more.

“They’re likely going to last longer than the buildings on campus,” Jeff Hammond, the executive director of the International Ground Source Heat Pump Association, said of Epic’s geothermal system.

Holly Braun, a co-founder of the Utility Networked Geothermal Collaborative, a group of gas utility companies that are interested in pursuing geothermal projects, said she would also like to know more about the cost of Epic’s geothermal system. However, Braun said that simply knowing a for-profit company installed geothermal heating and cooling at such a large scale is “intriguing.”

“They had to have economic reasons,” she added.

Growing Pains and Indefinite Growth

Brabender, the engineer with Salas O’Brien, first worked on the design of Epic’s growing geothermal system for a couple of years starting in 2012. After tackling other projects for a few years, he returned to Epic’s headquarters around 2017 and was told he would be there “indefinitely” to help the company as it continued to build out its heating and cooling system. Approximately eight years later, the soft-spoken engineer with black-rimmed glasses and a blond-stubble beard is still there.

“We had a lot of work and it just never stopped,” Brabender said as he drove past a 10-foot-tall toy soldier that appeared to be directing traffic as several dump trucks lumbered past. To his right, a half-dozen construction cranes towered above a former farm field as construction workers built “Other Worlds,” the latest storybook-themed campus at Epic’s headquarters.

Epic’s Schnabel cautioned, however, that a geothermal heating and cooling network may not be for everyone.

“In the absence of having advanced engineering staff, I’ve seen them gone awry,” he said. “It’s a newer technology that takes a little bit more investment in time and understanding to get it right.”

Epic’s engineers encountered some difficulties in the early years. The initial geothermal network wasn’t large enough to absorb all of the system’s heat during the summer. As a result, the initial borefield and surrounding rock and sediment were overheating, reducing the system’s efficiency.

In subsequent years, the company added thousands of additional boreholes to absorb more thermal energy. To shed additional heat when needed, Epic also added a pipe network at the bottom of a stormwater runoff pond and extra loops of pipe at the bottom of a flooded quarry.

“It was just growing pains,” said Tinjum, of the University of Wisconsin. “That campus was quickly growing, and the first field just couldn’t keep up with that capacity.”

Part of the excess heat comes from a data center at Epic’s headquarters. The geothermal network draws heat from the data center to cool it. Much of that heat is used to warm office spaces, supply hot water to some of Epic’s dining facilities and melt snow from sidewalks.

Additional heat is released through the quarry and pond, a non-beneficial use but one that, unlike cooling at most data centers, requires little energy and no additional water.

As Brabender continued his tour, he talked about some of the system’s challenges. Unlike most geothermal networks, which use a mix of glycol and water in their pipes, Epic uses only water. It allows the system to operate more efficiently, but also makes it potentially prone to freezing.

To ensure the system doesn’t overheat or get too cold, Brabender said he models usage as much as five years into the future.

As Epic continues to grow, Brabender said he sees plenty of work ahead on its expanding geothermal network.

“For right now,” he said, “I think [my assignment] is still indefinite.”

About This Story

Perhaps you noticed: This story, like all the news we publish, is free to read. That’s because Inside Climate News is a 501c3 nonprofit organization. We do not charge a subscription fee, lock our news behind a paywall, or clutter our website with ads. We make our news on climate and the environment freely available to you and anyone who wants it.

That’s not all. We also share our news for free with scores of other media organizations around the country. Many of them can’t afford to do environmental journalism of their own. We’ve built bureaus from coast to coast to report local stories, collaborate with local newsrooms and co-publish articles so that this vital work is shared as widely as possible.

Two of us launched ICN in 2007. Six years later we earned a Pulitzer Prize for National Reporting, and now we run the oldest and largest dedicated climate newsroom in the nation. We tell the story in all its complexity. We hold polluters accountable. We expose environmental injustice. We debunk misinformation. We scrutinize solutions and inspire action.

Donations from readers like you fund every aspect of what we do. If you don’t already, will you support our ongoing work, our reporting on the biggest crisis facing our planet, and help us reach even more readers in more places?

Please take a moment to make a tax-deductible donation. Every one of them makes a difference.

Thank you,