In many industries, it’s simply no longer practical to tackle air pollution management with “bolt-on” solutions, and you can’t address regulatory requirements such as BREFs by simply adding an appropriate filter or catalyst to a process. Envirotec explored the latest thinking in industrial air pollution management in conversation with Luhrfilter UK, a group with a focus entirely on custom-built systems that address challenging requirements in this space.

“We work to each clients’ specific operating permit,” says director Richard Jones, explaining that “each plant is tailored around the particular composition of gases”. The legally-enforceable limits will depend on the type of activity and the scale of emissions, and obviously, the geographic region (and its associated permitting requirements). Luhrfilter has customers, for example, situated in the middle of the Peak District National Park as well as in major cities and industrial centres.

Naturally, everywhere you look such requirements are getting tighter. The matter of how such targets are addressed is also becoming more complex, with greater rigour now expected with elements such as monitoring and reporting. The more recent requirement to adhere to Best Available Technique Reference Documents (BREFs) means not only tighter emissions limits, but also greater sophistication in control and monitoring. There is also a greater impetus to use newer technologies to remove problem gases.

Luhrfilter works with a wide range of industries, including non-ferrous metals (i.e., copper and aluminium production), clinical waste incinerators, and energy-from-waste plants. The group employs over 20 specialist engineers at the head office in Germany, each with expertise in a specific application area (such as biomass, copper foundries or EfW, for example). And the scope of services provided includes commissioning, engineering design and the manufacturing and installation of the equipment.

Energy-from-waste incineration plants present some of the more exacting specifications, says Richard, as they’re usually dealing with large gas volumes at elevated temperatures. They’re also, increasingly, incorporating NOx removal.

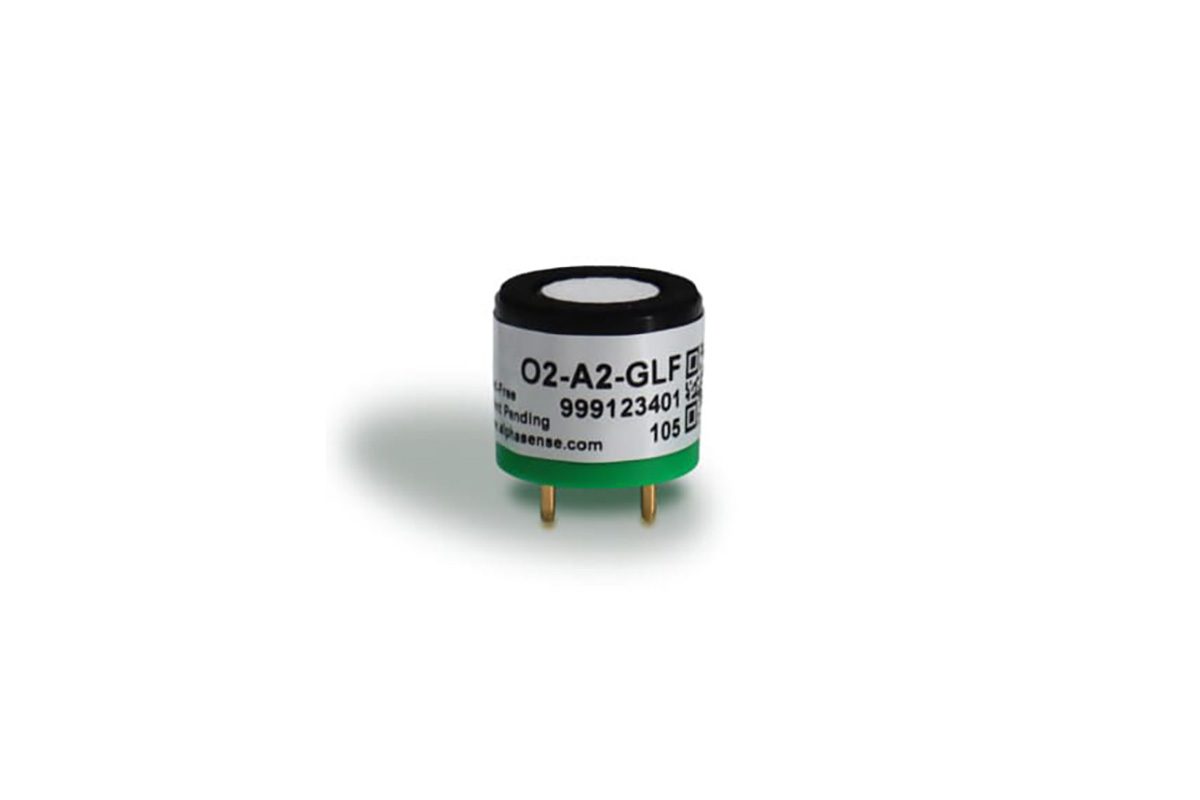

The group has provided a solution at a UK Refuse-Derived Fuel (RDF) Energy-from-waste plant (see image, above) designed to handle a crude gas input of 79, 850 Nm3/hr (humid) or 137,300 Am3/hr @ 190OC, and producing clean gas output specified with daily average emissions limits of particulates (10 mg/Nm3), SO2 (50 mg/Nm3), HCl (10 mg/Nm3), HF (1 mg/Nm3), Hg (0.05 mg/Nm3), dioxins / furans (0.1 ng/Nm3), and NOx (120 mg/Nm3).

EfW plant exhaust gases

There are three main areas within an EfW plant: the loading hall (incoming waste), thermal equipment (i.e. moving grate furnace and boiler), and the power generation system (i.e., turbine or generator). Exhaust gases from the second and third of these stages enters a process of flue gas treatment.

The Luhrfilter “scope of supply is typically everything from the back of the economizer to the outlet of the stack”, he says. In other words, they handle the flue gas after it has gone through the main heat-recovery stage. The firm provides all the necessary steps to prepare this gaseous material before it can be released to the atmosphere. This caninclude components such as the additive storage and dosing systems, pre-separation, evaporative coolers, dust separation, NOx removal,residue conveying and storage silos, ID fans and the exhaust stack.

EfW plants will require the removal of furans and dioxins, for example, which will involve the addition of powdered activated carbon (PAC), a porous dust to which these problem gases adsorb. PAC will be introduced to the flue gas, in a reaction chamber, prior to a bag filter stage, where the contaminant-coated carbon material is collected for disposal as hazardous waste.

Acid gases such as sulphur dioxide and hydrogen fluoride, on the other hand, can be removed from flue gas by the injection of hydrated lime: a dry, fine powder of calcium hydroxide. The lime neutralizes the acids while suspended in this gas flow, and forms calcium salts that are, again, collected in the bag filter.

Cunning chemistry

The subtlety of the chemistry makes this an important step to get right, and some of it is temperature dependent, meaning the temperature has to be kept within a specific range: Too hot and it cooks, too low and the process is inefficient. This might be especially apparent with a clinical waste incinerator, where the flue gas needs to be cooled from around 850 C to something like 180-200 C, an operation that can be accomplished by evaporative coolers or heat exchangers, allowing the temperature to be controlled to within a few degrees.

There’s a lot of chemical engineering involved in air pollution management, he explains.

With NOx removal, for example, it involves understanding the behaviour of catalysts and optimising performance. In Selective Catalytic Reduction (SCR), the flue gas is passed over a catalyst – different materials are used here such as titanium dioxide, vanadium pentoxide, tungsten trioxide, or zeolites – while an ammonia solution is injected. The catalyst accelerates the chemical reaction that converts NOx gases into nitrogen and water.

There are subtleties to the way the catalyst is deployed here, with optimal performance requiring a balance of parameters like temperature, dust content, and ensuring catalyst performance is not impaired by other flue gas components. This is another area where the requirement for innovation seems to be growing.

Another emerging requirement for EfW plants is carbon capture. DEFRA announced rules in January that mean new waste incinerators will only receive planning approval if they meet a number of conditions, one of which will be to show that they are “carbon-capture ready”, and able to show how they will use any waste heat that is produced.