This article contains paid for content produced in collaboration with Arvia.

Regulations for the use of 1,4-dioxane tightened up in the US, putting pressure on chemical manufacturers. Several US states passed laws to control the concentration of 1,4-dioxane as a product ingredient. The new laws did not yet affect wastewater concentrations, but it seems a foregone conclusion that this would happen.

Client: Global Life Sciences and Consumer Care Company

The client had faced questions from many customers as to their use of 1,4-dioxane, in the light of US regulation changes. Simultaneously the board had set some challenging CSR goals in response to the situation, in an effort to do the right thing and gain competitive advantage.

The UK headquarters set up a global team to meet and discuss 1,4-dioxane removal at their ethoxylation sites across the world. This included Europe, Asia and the US.

Problem: To reduce 1,4-dioxane to <0.3ppb

After reviewing BAT for 1,4-dioxane removal from water, they approached Arvia Technology to help ensure they did not discharge more than 0.3ppb at any time.

Solution

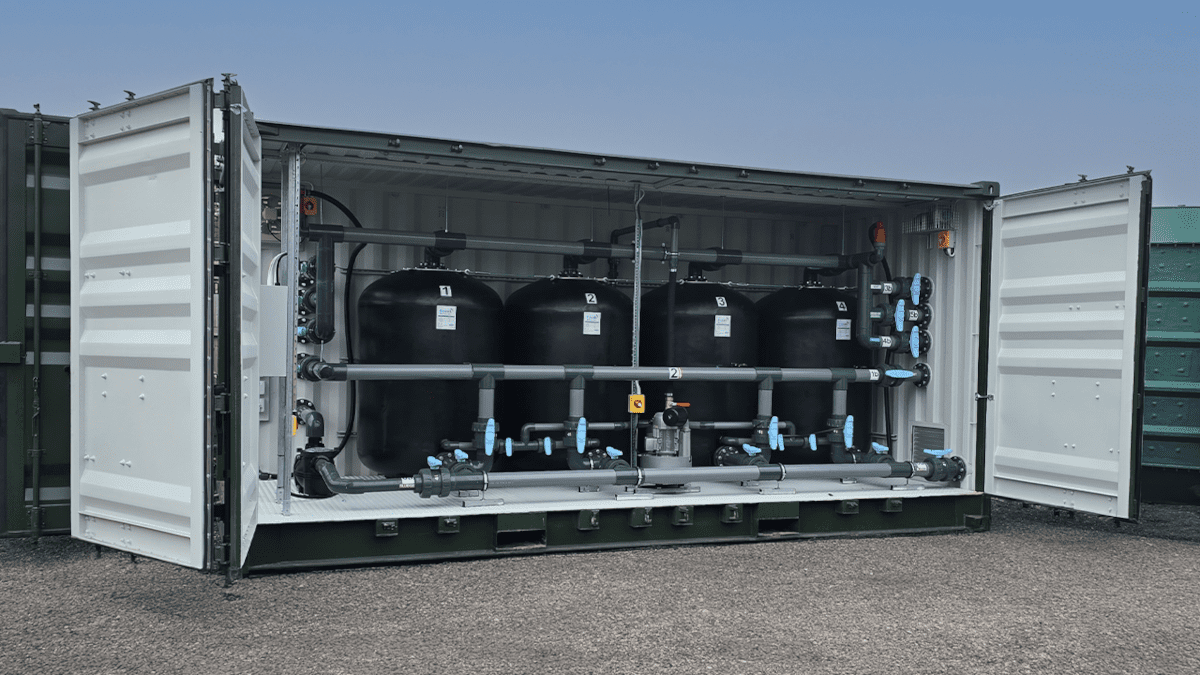

Arvia is a leading electrochemical oxidation expert and has developed a range of water treatment systems which target persistent organic chemicals such as 1,4-dioxane. See here.

Nyex Ellenox was piloted at Arvia’s UK HQ and was able to reduce 1,4-dioxane from 1800mg/L to 0.2ppb, well below the target.

Simon Gatcliffe, Arvia’s CEO explained, “We’ve demonstrated we have a solution to support our global clients having met US state level requirement of <0.46ppb. Our Ellenox system uses electrochemical oxidation to mineralise organic pollutants. We have tuned every aspect of the design and now achieve very competitive OpEx.”

Result

The client is now looking to roll out full scale plants at their US sites. Following successful installation, they plan to cover all of their production sites which use 1,4-dioxane.

To find out more, visit their website.